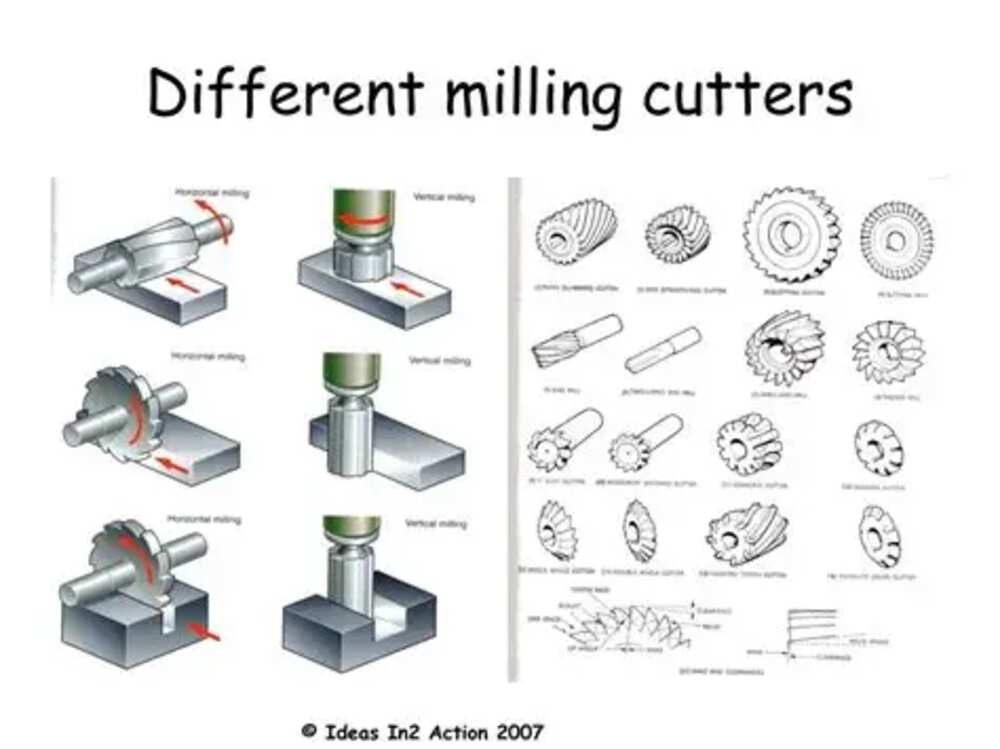

In the world of home construction, renovation, and metal or wood fabrication, precision is everything. Whether shaping custom cabinetry, creating fittings, or machining components for structural installations, milling cutters play a critical role. Understanding the different types of milling cutters and how they function helps professionals choose the right tool for every job—improving efficiency, accuracy, and finish quality.

Below, tokohasil.com look at the most common types of milling cutter tools, their specific uses, and practical insights into how they’re applied across home and building projects.

1. End Mills: The All-Rounder Workhorse

End mills are among the most versatile tools in any milling setup. They cut horizontally, vertically, and even at angles, making them suitable for everything from slotting and profiling to contouring complex shapes.

- Flat End Mills: Ideal for cutting flat surfaces and sharp edges, often used in woodworking, door frame fabrication, and fixture construction.

- Ball Nose End Mills: Feature a rounded tip that’s perfect for contouring, 3D milling, and decorative finishes. These are popular for producing smooth edges on furniture components or moldings.

- Corner Radius End Mills: Combine strength and precision, useful for parts that need durability without sharp internal corners.

When it comes to home and building applications, end mills are a go-to for precision shaping of metals, plastics, and engineered wood materials.

2. Face Mills: For Wide, Smooth Finishes

Face mills are designed for high-efficiency surface cutting. With multiple cutting inserts around the edge, they remove large amounts of material quickly while leaving a smooth, even surface.

These tools shine in operations such as:

- Leveling large panels or beams before assembly.

- Preparing metal sheets for fitting or welding.

- Producing smooth finishes on countertops or frame joints.

Face milling tools are commonly used in cabinetry workshops and metal fabrication shops where consistent flatness and finish are crucial.

3. Slab Mills: Built for Heavy-Duty Cuts

When the job calls for serious material removal, slab mills take the lead. They’re large, cylindrical cutters designed for machining broad surfaces in one pass.

In construction-related manufacturing, slab mills are often used to:

- Plane metal or hardwood blocks for base structures.

- Shape beams or supports to exact dimensions.

- Prepare large workpieces for further milling or drilling.

Their wide cutting area makes them efficient for both speed and volume—perfect for shop settings that handle bulk production.

4. Side and Face Cutters: For Grooves and Slots

As the name suggests, side and face cutters cut on both the sides and the periphery, making them ideal for producing deep slots, grooves, or keyways.

Applications include:

- Cutting channels in aluminum or steel fixtures.

- Creating joints for wood framing or cabinetry.

- Slotting grooves for window and door tracks.

In home and building industries, these cutters are essential when precision alignment and tight fitting are required.

5. T-Slot Cutters: Precision for Interlocking Structures

T-slot cutters are specialized tools designed to create T-shaped grooves—common in work tables, fixtures, and machine bases.

These grooves allow bolts or components to slide in for adjustable positioning, a feature valued in modular construction and woodworking setups. For professionals, T-slot milling is a key process when creating custom jigs or adjustable assembly tables.

6. Fly Cutters: Simple Yet Effective

Fly cutters use a single-point cutting tool mounted on a rotating arm. Though simple in design, they can produce an exceptional surface finish on large, flat areas.

Their low-cost setup and high-quality finish make them popular for:

- Finishing tabletops, doors, and wooden panels.

- Leveling metal plates before fabrication.

- Achieving high precision in custom one-off parts.

For workshops focusing on home interiors or architectural metalwork, a fly cutter is an essential finishing tool.

7. Gear Cutters and Form Milling Cutters: Specialized Precision

For more advanced machining, gear cutters and form milling cutters come into play.

Gear Cutters are used to create the teeth of gears, useful in mechanisms like sliding doors or adjustable fixtures.

Form Milling Cutters are shaped to reproduce complex contours or decorative moldings directly, reducing manual sanding or carving time.

These tools are invaluable when working with detailed components in high-end home projects or precision architectural metalwork.

Choosing the Right Milling Cutter

Selecting the right milling cutter depends on three main factors: material, finish requirements, and production scale. For example, an end mill might suit a small cabinetry project, while slab or face mills are better for heavy-duty frame machining. Using high-quality, coated cutters also extends tool life and ensures cleaner cuts—saving time and cost in the long run.

Final Thoughts

In modern home and building fabrication, the choice of milling cutter directly impacts craftsmanship, speed, and precision. Understanding each tool’s purpose—from the versatility of end mills to the power of slab cutters—empowers professionals to work smarter and deliver superior results.

Investing in the right milling cutters isn’t just about getting the job done; it’s about elevating quality, consistency, and efficiency in every project.