If you’ve worked in the medical device space for even a short while, you’ve probably heard someone mention ISO 13485 certification with a tone that’s half admiration, half exhaustion. And honestly, that makes sense. The standard is essential, but it can feel like a giant puzzle—especially for companies trying to grow, innovate, and still keep every regulator happy. Yet, here’s the thing: once you understand why ISO 13485 matters and how it shapes your entire quality management approach, it stops feeling like a burden and starts feeling like a competitive advantage you can’t imagine working without.

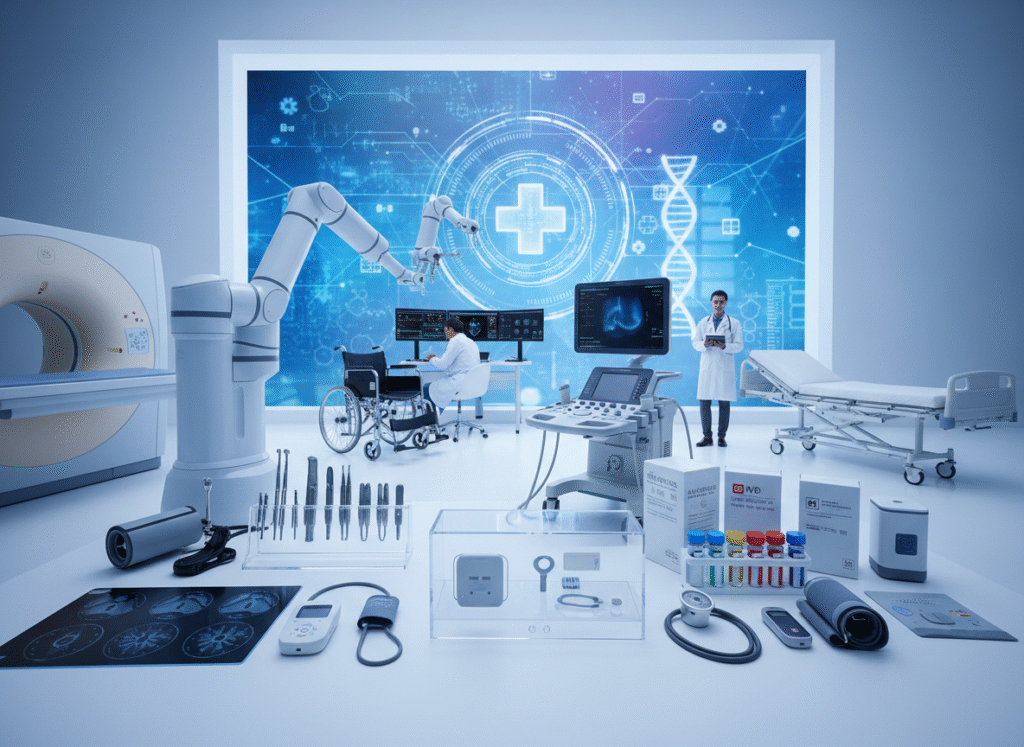

Before we get into the thick of it, let’s set the scene. ISO 13485 isn’t just a “nice to have.” It’s the backbone for medical device quality systems across global markets. The moment you’re supplying components, assembling devices, packaging sterile products, or developing software that touches healthcare—this standard becomes part of your daily vocabulary.

And yes, sometimes you’ll catch yourself quoting clause numbers at odd moments. It happens.

Why ISO 13485 Matters More Than People Admit

ISO 13485 has earned its reputation because it’s built for the medical device industry’s real challenges—not the theoretical ones. It forces companies to build a reliable Quality Management System (QMS) that controls every step, from design and development to packaging, distribution, and even post-market processes like complaint handling. You know what? These requirements aren’t just for passing audits—they’re what help manufacturers avoid product failures, regulatory penalties, and recalls that can devastate a company.

For new manufacturers, especially those scaling quickly, the certification acts like a stabilizer. It ensures that product quality doesn’t crumble under pressure. And for suppliers trying to stay competitive, being certified sends a loud message: “We take safety seriously, and we’re ready for global business.”

Many global device brands expect their partners to hold ISO 13485 certification, and without it, you’re often out of the running before the conversation even starts. It’s like showing up to a formal event without shoes—no one’s going to let you walk in.

Regulatory Expectations: Because Compliance Never Sleeps

If you manufacture devices for Europe, Canada, Australia, or many parts of Asia, ISO 13485 is practically synonymous with compliance. Regulators lean heavily on this standard because it gives them confidence that a manufacturer has a real QMS—not a paper one.

In Europe, ISO 13485 supports CE marking. In Canada, it’s a regulatory requirement. In several markets, it’s the only recognized QMS model.

The global demand is why terms like medical device QMS, ISO 13485 requirements, risk-based approach, device traceability, and regulatory compliance keep dominating conversations. They’re not buzzwords—they’re daily realities.

It’s also why more manufacturers integrate ISO 14971 for risk management or use digital tools like Greenlight Guru, MasterControl, and TrackWise. These platforms make record-keeping less painful, especially for smaller teams juggling audits, development cycles, and production schedules at the same time.

How ISO 13485 Certification Strengthens Your Market Reputation

The certification does more than satisfy regulators. It tells customers—especially big medical device brands—that your operations are predictable, controlled, and safe. Many OEMs request ISO 13485 certified suppliers because they simply don’t want to risk product failures traced back to poor-quality components or weak QMS structures.

Your certification becomes a silent sales tool. It reassures clients before you even present a proposal. When customers see terms like quality assurance for medical devices, ISO 13485 compliance, or certified medical device supplier on your profile, the trust instantly increases.

Sometimes you’ll notice the difference unexpectedly. For example, during vendor qualification calls, people stop asking certain questions because certification already answers them.

Internal Benefits You Might Not Expect

Manufacturers often focus on the external benefits, but what happens inside your organization is even more valuable. Teams communicate better. Processes become predictable. Mistakes show up earlier. Departments stop working in isolation. And suddenly, everyone knows exactly how a change request moves—from engineering to quality to production.

It’s like switching from a busy street with no traffic lights to a smooth, well-managed system. Everything flows with fewer close calls.

There’s also the sense of pride. Employees feel more confident when they know the system protects them from errors and gives them clear roles. When inspectors walk in, your team doesn’t panic. They know the story behind their processes.

A Quick Look at Real-World Scenarios

Let’s say a supplier manufactures PCB assemblies for a wearable cardiac device. Without ISO 13485, the OEM needs extra audits, extra inspections, and extra risk controls. But when the supplier is certified, half that work disappears. The OEM already trusts the built-in controls.

Or picture a manufacturer producing sterile packaging. Sterilization validation, traceability, environmental monitoring—these aren’t optional. The moment a regulator walks in, they’ll ask for everything from employee training to batch release records. An ISO 13485 certified company has these records ready and organized.

If you’ve ever been in a surprise inspection before, you know how much that matters.

Supplier Control Under ISO 13485

You might already know this, but suppliers can make or break your quality system. One faulty batch of material can shut down production for days or even trigger a recall. ISO 13485 helps you evaluate suppliers based on performance, audit results, certificates, and continued compliance. This is especially important if you’re dealing with sterilization service providers, machining companies, or software developers.

Even a simple contract manufacturer must be monitored. Their mistake is your liability.

Some manufacturers use scorecards; others use quarterly reviews. The key is consistency—because regulators always ask, “How do you know your supplier remains qualified?” If your answer sounds confident, half the battle is won.

Documentation: The Part Everyone Complains About

Documentation has a bad reputation, but in an ISO 13485 system, it becomes your safety net. Procedures, work instructions, forms, validation records—they exist to protect the company. They also help new employees learn faster and reduce reliance on memory or informal habits.

The trick is to keep documents easy to read. Avoid long blocks of text. Use simple language. And always store documents in a place where people can find them.

A complicated QMS is a broken QMS. If people avoid your documents, something needs fixing.

Why ISO 13485 Certification Isn’t a One-Time Achievement

Certification lasts three years, but surveillance audits happen every year. Companies that ignore their QMS between audits always struggle. The standard demands ongoing maintenance: internal audits, CAPAs, management reviews, and continuous improvement.

That phrase—continuous improvement—can sound repetitive, but in the medical device space, it has real meaning. Every new complaint, every trend, every batch failure gives you information. ISO 13485 pushes you to act on it.

Think of it like maintaining a machine. If you wait until it breaks, the repair will cost more and take longer. But small adjustments keep everything running smoothly.

Final Thoughts: ISO 13485 Is More Than a Certificate—it’s a Mindset

Once your organization embraces ISO 13485, everything changes. People start thinking differently about quality. Teams collaborate more. Problems surface earlier. And your reputation in the medical device industry strengthens naturally.

Sure, the certification takes effort. But for manufacturers and suppliers aiming to serve global markets, it’s the strongest foundation you can build.

And honestly, when a customer asks, “Are you ISO 13485 certified?”—it feels good to say yes without hesitation.