Hydraulic Press Machine Supplier: Powering Industrial Efficiency

The manufacturing world relies heavily on advanced machinery that drives precision, productivity, and performance. Among these, the hydraulic press machine stands out as one of the most essential tools used across industries for molding, shaping, and compressing materials. Behind the reliability and performance of these machines lies the vital role of the hydraulic press machine supplier. These suppliers are the link between modern manufacturing needs and high-performance mechanical solutions, ensuring industries have access to machines designed for precision, safety, and durability.

Understanding Hydraulic Press Machines

At its core, a hydraulic press operates on Pascal’s law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows hydraulic machines to produce enormous force from a relatively small input. The setup usually includes a hydraulic cylinder, piston, and pump system filled with hydraulic fluid. When pressure is applied, the piston moves, exerting powerful compressive force on the material placed below.

Hydraulic presses are versatile and can perform a wide range of tasks such as punching, bending, forming, forging, drawing, and compacting. Compared to mechanical presses, they offer consistent pressure throughout the entire stroke, ensuring greater accuracy and control. This makes them suitable for industries where precision and consistent results are paramount.

Types of Hydraulic Press Machines

Hydraulic press machines come in various forms, each designed for specific applications and workspace requirements.

- C-Frame Hydraulic Press: Compact and accessible, ideal for tasks like straightening, punching, or riveting light to medium materials.

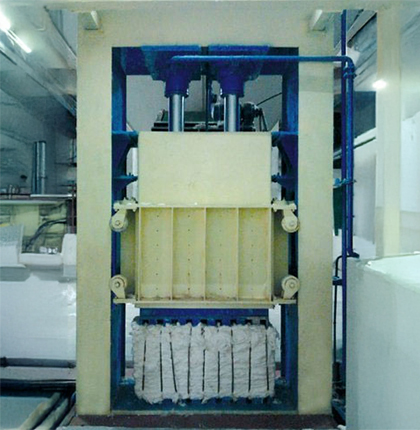

- H-Frame Hydraulic Press: Known for its strength and versatility, used in heavy-duty applications including pressing, bending, and assembly.

- Four-Column Hydraulic Press: Offers even pressure distribution and stability, often used in large-scale manufacturing operations such as deep drawing and forming sheet metal.

- Deep Drawing Press: Specially designed for shaping flat metal sheets into hollow shapes such as cylinders and kitchenware.

- Automated Hydraulic Press: Equipped with sensors, programmable logic controllers (PLCs), and digital safety features to improve precision and reduce human error.

A reliable supplier understands the diversity of these machines and helps manufacturers select the best model for their operational needs.

The Role of a Hydraulic Press Machine Supplier

A hydraulic press machine supplier does much more than provide equipment. Their role extends into consultation, customization, installation, and long-term support. They act as technology partners, ensuring that manufacturers achieve maximum efficiency, safety, and longevity from each machine.

- Consultation and Needs Assessment: Every industrial process is unique. Suppliers guide buyers in choosing presses with the appropriate tonnage, working pressure, and configuration.

- Customization: Presses are often tailored to specific production targets or material requirements. Modifications in frame design, hydraulic systems, or control panels can optimize the machine’s function for specialized applications.

- Quality Standards: Trustworthy suppliers maintain high manufacturing standards and test each machine against safety and performance benchmarks.

- Support and Maintenance: Regular maintenance, spare parts availability, and operator training ensure smooth operation and reduced downtime.

- Technological Advancements: Modern suppliers integrate automation and energy-saving technologies, enhancing precision while reducing operational costs.

Through these services, suppliers contribute not only to machine longevity but also to improving overall manufacturing efficiency.

Applications Across Industries

Hydraulic press machines serve a wide spectrum of industries, from automotive and aerospace to construction and materials processing. In the automotive sector, presses shape components like body frames, brake pads, and engine parts. In metal fabrication, they cut, bend, and mold metallic sheets. The electrical industry uses them to form insulators and enclosures, while the plastics and rubber industries rely on hydraulic presses for molding and compaction. Even in artisanal workshops and laboratories, smaller versions of these presses are used for precision tasks.

This versatility across industries highlights the importance of choosing a supplier who understands different market needs and technological standards.

Selecting the Right Supplier

Choosing the ideal hydraulic press machine supplier requires careful consideration of several factors:

- Industry Experience: A knowledgeable supplier can recommend the most efficient solution for specific applications.

- Product Diversity: A wide portfolio allows buyers to find the exact type and capacity needed.

- Customization Options: Flexibility in design and operation ensures optimal machine performance.

- After-Sales Support: Reliable maintenance services and quick spare part delivery can prevent costly delays.

- Innovation: Suppliers investing in smart technologies and eco-friendly systems help manufacturers stay competitive.

A good partnership with a supplier ensures superior machine performance, reduced operational costs, and long-term reliability.

The Future of Hydraulic Press Technology

The hydraulic press industry is evolving alongside Industry 4.0 advancements. Smart hydraulic presses now feature sensors and data analytics for real-time monitoring and predictive maintenance. Energy-efficient drives and eco-friendly hydraulic systems are reducing power consumption while improving precision. As automation and digitalization continue to expand, hydraulic press machine suppliers will remain pivotal in helping industries transition to intelligent, efficient, and sustainable production.

Conclusion

Hydraulic press machine suppliers are essential partners in the growth of modern manufacturing. They combine engineering expertise, technical support, and innovation to provide solutions that empower industries to produce faster, safer, and with greater accuracy. As technology continues to advance, the right supplier will not only provide equipment but also contribute to shaping a smarter and more efficient industrial future.

URL: For more information, visit Suvera Fluid Power: Hydraulic Press Machine Supplier