Across regional Queensland, the rise in demand for high-performance work vehicles has driven a renewed appreciation for custom fabrication. For tradespeople, farmers, and off-road enthusiasts, a ute is more than just transport — it’s a mobile workspace and a statement of reliability. Nowhere is that craftsmanship more evident than in ute tray fabrication Miriam Vale, where function meets precision in every weld and finish.

The Growing Demand for Custom Ute Trays in Regional Australia

In towns across regional Queensland, customized ute trays have become indispensable. Local industries — from agriculture and mining to construction — depend on vehicles that can carry heavy loads and withstand punishing terrain. Off-the-shelf options rarely meet these specific needs, prompting many ute owners to seek custom fabrication services that balance strength, design, and functionality.

Workshops in smaller towns like Miriam Vale have developed a reputation for combining local knowledge with skilled engineering. The result is trays built to match each driver’s requirements — whether that means reinforced under-tray storage, adjustable headboards, or corrosion-resistant finishes designed for coastal conditions. In this way, ute tray fabrication Miriam Vale isn’t simply about utility; it’s about creating tools that last generations.

For readers interested in the evolution of local manufacturing, check out Australia’s Engineering Traditions and Rural Craftsmanship — a deep dive into the regional industries that drive innovation.

Turning Vehicle Needs into a Design Blueprint

Every great ute tray begins with a conversation. Fabricators start by understanding how a vehicle is used: what it carries, how often it travels, and under what conditions. These discussions form the blueprint for a design tailored to the driver’s workday. Measurements are taken to ensure a seamless fit, from the cab to the rear bumper, while considering any accessories or toolboxes to be added later.

Modern workshops use CAD software and digital modelling to create precise designs before a single piece of metal is cut. This technology ensures every tray aligns perfectly with the vehicle chassis and maintains balanced weight distribution for safer handling.

Precision and adaptability are hallmarks of Miriam Vale ute tray fabrication by Stewart and Sons — a workshop known for turning functional requirements into well-engineered concepts built for the demands of Australian roads.

You can explore similar insights on Behind Australia’s Best Fabrication Practices, which outlines the technical standards shaping modern engineering workshops nationwide.

Material Selection: Strength Meets Longevity

Selecting the right material is a critical step in the fabrication process. For heavy-duty applications, steel remains a popular choice thanks to its unmatched strength and load capacity. However, aluminum and alloy options are increasingly favored for their corrosion resistance and lighter weight, making them ideal for trades that require agility and fuel efficiency.

Miriam Vale’s local fabricators understand that the Queensland climate demands extra care in material choice. The intense sun, coastal humidity, and occasional road salt can shorten a tray’s lifespan if the wrong metal or finish is used. By focusing on high-grade, locally sourced materials, workshops ensure that trays maintain both structural integrity and visual appeal.

This commitment to quality materials mirrors a broader trend in Australian engineering, where sustainability and durability are becoming intertwined. Readers may find value in How Sustainable Materials Are Changing Australian Manufacturing — an informative feature on shifting material practices in regional industries.

The Fabrication Process: Precision in Every Weld

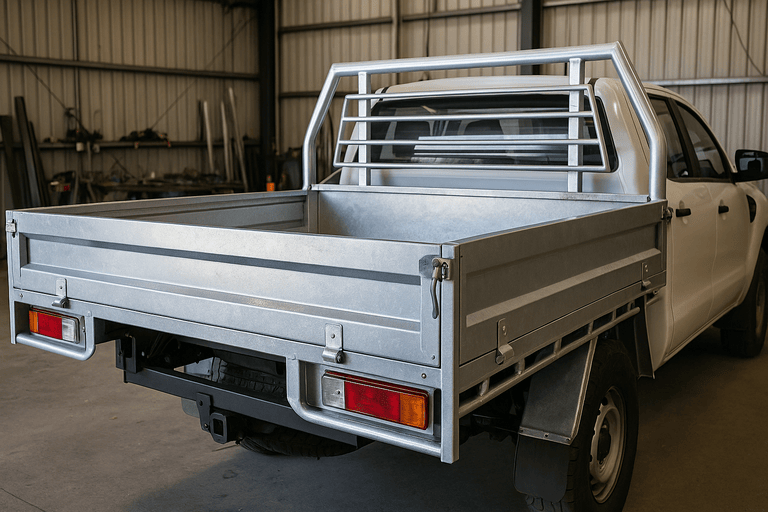

Once the design is finalized and the material prepared, fabrication begins. This is where craftsmanship takes centre stage. Sheets of alloy or steel are cut to specification using laser-guided machinery, ensuring absolute precision. Components are bent and shaped to match the design blueprint before being joined through MIG or TIG welding — processes known for their strength and durability.

Each weld is inspected for accuracy, ensuring there are no weak points that could fail under pressure. Edges are ground smooth, and every part is checked for alignment before final assembly. The tray is then sandblasted, primed, and finished — often with a durable powder coating that resists chips and rust.

Workshops such as Miriam Vale ute tray fabrication by Stewart and Sons exemplify this attention to detail. Their trays are engineered to handle Australia’s toughest work conditions, combining modern equipment with the traditional values of local workmanship.

For those who enjoy learning about trades innovation, The Role of Fabricators in Modern Australian Trades offers further insight into the people behind these essential industries.

Finishing Touches and Custom Features

After the main structure is complete, the finishing stage turns a sturdy frame into a highly functional work platform. Ute owners can request a range of add-ons — from under-tray toolboxes and tie-down points to ladder racks, LED lighting, or powder-coated finishes in custom colors. Each addition transforms the tray from a generic accessory into a purpose-built asset.

Attention to small details, such as concealed wiring or precision-cut headboards, ensures the final product not only performs well but also looks professional. For many tradies, this finish reflects their own standard of work — durable, clean, and built to last.

Across Queensland, these local workshops show how craftsmanship and practicality can coexist in design. Custom ute tray fabrication Miriam Vale has set a standard that balances visual appeal with functional excellence.

Why Local Fabrication Matters

Choosing a local fabricator isn’t just about convenience; it’s about trust and community investment. Local workshops understand the specific needs of regional industries — from towing farm equipment to navigating off-road worksites. They may offer shorter turnaround times, direct communication, and the ability to customize on-site.

Supporting regional engineering also strengthens the local economy, creating apprenticeships and sustaining family-owned workshops that pass down expertise through generations. It ensures that the craftsmanship developed in towns like Miriam Vale continues to thrive and evolve.

This connection between business and community is a key part of why regional fabrication remains an integral part of Australia’s industrial identity. For a closer look at these economic benefits, readers can explore Supporting Regional Manufacturing in Australia.

Conclusion

The art of ute tray fabrication Miriam Vale represents more than just vehicle modification — it’s a reflection of Australia’s deep-rooted engineering culture. From concept design to the final powder-coated finish, every step showcases dedication, precision, and the spirit of local enterprise.

Whether it’s for a farmer hauling supplies, a tradesperson managing tools, or a driver who simply values reliability, locally fabricated trays offer unmatched quality and longevity. The workshops leading this craft, such as Miriam Vale ute tray fabrication by Stewart and Sons, stand as examples of how technical mastery and regional pride can drive innovation across Australia’s automotive landscape.