Nylon Net Manufacturers

When it comes to safety, durability, and long-term performance, Nylon Net Manufacturers play a crucial role in supplying high-quality nets for construction sites, industrial spaces, sports activities, warehouses, and agricultural applications. As industries continue to adopt advanced safety solutions, the demand for premium nylon nets is rising due to their exceptional strength, elasticity, and weather-resistance. Choosing the right manufacturer ensures reliable protection and long-term value for various commercial and industrial uses.

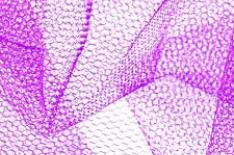

Nylon is known for its high tensile strength, shock absorption, and excellent flexibility, making it a preferred material for safety nets, cargo nets, bird protection nets, and sports nets. With the increasing use of modern technology, manufacturers now focus on precision engineering, UV-stabilization, and long-lasting knotting techniques to deliver superior netting solutions that meet diverse industry standards.

Why Nylon Nets Are in High Demand Across Industries

One of the biggest advantages of nylon is its remarkable durability. This makes nylon nets ideal for construction safety nets, industrial nets, sports nets, cargo nets, agricultural nets, and bird nets. Whether used for fall protection, load securing, crop protection, or sporting activities, nylon’s ability to withstand heavy loads and harsh climates gives it a clear advantage over other materials like polyester or polypropylene.

High-quality nylon nets offer benefits such as:

- Superior flexibility and stretch

- Strong impact resistance

- Excellent abrasion resistance

- Weather and UV stability

- Long service life

These features make nylon the preferred choice for industries seeking reliable and long-lasting protection solutions.

How Leading Manufacturers Produce High-Strength Nylon Nets

Reputed manufacturers follow a multi-stage production process designed to ensure optimal performance and consistent quality. The manufacturing steps usually include:

1. High-Quality Raw Material Selection

Manufacturers use premium-grade nylon fibers that are UV-treated, weather-resistant, and capable of handling high tension. This ensures durability even under tough outdoor conditions.

2. Advanced Weaving and Knotting Techniques

Modern machines are used for precision weaving, braiding, and knotting. Techniques such as single mesh knotting, diamond mesh weaving, and border rope reinforcement help improve net stability and load-bearing capacity.

3. Quality Testing and Certification

Each nylon net undergoes strict quality checks, including tensile testing, load testing, weather resistance testing, and abrasion tests. Many manufacturers follow ISO standards to meet global safety requirements.

4. Customization Options

Top nylon net producers provide customized sizes, mesh thickness, rope diameters, colors, and design options based on industry needs. Customized nets are widely used in construction, industries, warehouses, and sports facilities.

Applications of Nylon Nets in Modern Sectors

Nylon nets are widely used across multiple industries. Some key applications include:

• Construction Safety Nets

Ideal for preventing falls, debris control, and worker safety.

• Industrial & Warehouse Safety

Used to protect goods, prevent accidents, and secure storage spaces.

• Agricultural Nets

Farmers use nylon bird protection nets, crop covers, and fencing nets.

• Sports Nets

Commonly used in cricket nets, football nets, badminton nets, and golf practice nets.

• Cargo & Load Securing Nets

Perfect for transport, logistics, and heavy load handling.

With such diverse uses, industries rely heavily on skilled Nylon Net Manufacturers for consistent quality and safety assurance.

How to Choose the Best Nylon Net Manufacturer

Selecting the right manufacturer is essential for ensuring long-term safety and product reliability. Here are some key factors to consider:

Quality of Raw Material

Always choose manufacturers who use premium-grade nylon and UV-stabilized fibers.

Manufacturing Technology

Look for producers using automated machinery and advanced weaving techniques.

Certification & Quality Control

ISO-certified manufacturers ensure consistent performance and adherence to international standards.

Customization Capabilities

The ability to tailor mesh size, rope thickness, design, and dimensions is crucial for industry-specific needs.

Industry Experience

Manufacturers with years of expertise deliver better engineering, guidance, and product reliability.

Conclusion

Choosing the right Nylon Net Manufacturers ensures durable, high-performance nets suitable for construction, agriculture, sports, warehouses, and industrial applications. With superior strength, flexibility, and long-lasting quality, nylon nets remain one of the most reliable solutions for safety and protection in modern industries. For businesses seeking dependable netting solutions, partnering with a trusted nylon net manufacturer can significantly enhance safety, efficiency, and long-term value.

Other Recommendations: Nylon Mesh Fabric Manufacturers