Bedaquiline Manufacturer: Understanding the Production of a Critical Anti-TB Drug

Bedaquiline has become one of the most important breakthroughs in the treatment of multidrug-resistant tuberculosis (MDR-TB). Approved in recent years as a key component of modern MDR-TB regimens, this drug has significantly improved recovery rates and reduced treatment durations for thousands of patients worldwide. While much attention is given to its clinical impact, an equally important aspect is the process and considerations involved in manufacturing bedaquiline. Understanding how this medicine is produced—from raw material synthesis to final quality assurance—highlights both the scientific and regulatory rigor behind one of the world’s most vital anti-TB drugs.

What Is Bedaquiline?

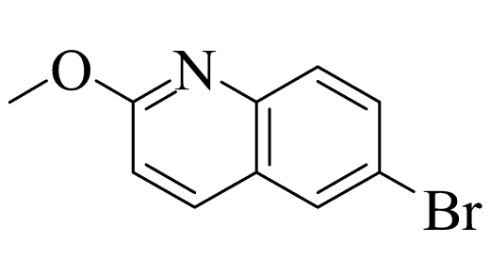

Bedaquiline belongs to a class of drugs known as diarylquinolines. Its unique mechanism targets mycobacterial ATP synthase, an enzyme essential for energy production in Mycobacterium tuberculosis. By inhibiting this enzyme, bedaquiline disrupts the bacteria’s energy supply and leads to cell death. Because of this targeted mechanism, bedaquiline has demonstrated effectiveness where many traditional TB drugs fail, making it a cornerstone therapy for resistant forms of the disease.

The Role of a Bedaquiline Manufacturer

Manufacturers of bedaquiline are responsible for converting complex chemical compounds into a safe, effective, and stable pharmaceutical product. Producing this medication requires advanced capabilities in chemical synthesis, industrial-scale process management, and strict compliance with global regulatory standards. A manufacturer must ensure that every step—from procuring raw reagents to final packaging—meets stringent quality expectations to guarantee patient safety.

Key Stages in Bedaquiline Production

- Active Pharmaceutical Ingredient (API) Synthesis

The heart of bedaquiline manufacturing lies in producing the Active Pharmaceutical Ingredient (API). Its synthesis is a multistep chemical process involving:

- Preparation of diarylquinoline intermediates

- Stereoselective chemical reactions

- Purification of intermediates

- Final crystallization to achieve the correct polymorphic form

Because bedaquiline’s structure is complex, API production demands advanced organic chemistry expertise, precision control of reaction conditions, and high-purity reagents. Even minor deviations can impact drug safety, potency, or stability.

- Formulation into Dosage Form

After producing the API, manufacturers convert it into a usable dosage form. Bedaquiline is commonly formulated as tablets that ensure:

- Uniform drug distribution

- Consistent dissolution and absorption

- Chemical stability throughout shelf life

Excipients—including stabilizers, fillers, and binding agents—are carefully chosen to support bioavailability and durability.

- Quality Testing and Validation

At every stage, rigorous testing is performed to ensure compliance with regulatory standards. This includes:

- Purity testing using chromatographic methods

- Stability studies under various environmental conditions

- Microbiological testing to ensure sterility and safety

- Dissolution testing to guarantee proper release in the body

Manufacturers must validate their processes to ensure reproducibility and batch-to-batch consistency. Quality control labs rely on advanced analytical technologies such as HPLC, NMR, and mass spectrometry.

- Packaging and Distribution

After formulation and testing, bedaquiline tablets are packaged into moisture-resistant blister packs or bottles. Proper packaging is essential because the drug is sensitive to environmental conditions such as heat, humidity, and light. Labels include essential details such as dosage instructions, manufacturing dates, and compliance information.

Regulatory Compliance and Global Standards

Manufacturing bedaquiline requires meeting international regulatory requirements due to its role in public health programs. Manufacturers must adhere to:

- Good Manufacturing Practices (GMP)

- World Health Organization (WHO) prequalification guidelines

- Local drug authority approvals

- Pharmacovigilance and post-market monitoring obligations

Compliance ensures that every batch produced is safe, effective, and suitable for global TB control initiatives.

Challenges in Bedaquiline Manufacturing

Manufacturers face several challenges, including:

- Complex synthesis pathways that require high technical expertise

- Costly raw materials and production processes

- Need for advanced equipment for API purification and formulation

- Stringent regulatory scrutiny due to the drug’s importance

- Demand forecasting difficulties, as MDR-TB burden varies across regions

Despite these challenges, the global demand for bedaquiline continues to rise as countries adopt modernized MDR-TB treatment regimens.

Why Reliable Manufacturing Matters

Bedaquiline’s significance in combating MDR-TB cannot be overstated. A reliable supply chain ensures that:

- Patients receive uninterrupted treatment

- Treatment outcomes remain high

- Drug resistance does not worsen due to stockouts

- Public health programs can plan and implement strategies effectively

Manufacturers contribute directly to global TB elimination efforts by ensuring the drug is accessible, affordable, and high-quality.

Conclusion

The manufacturing of bedaquiline is a sophisticated process that combines chemistry, engineering, and pharmaceutical science with strict adherence to global quality standards. Although the drug itself commands attention for its effectiveness against resistant tuberculosis, the expertise and precision behind its manufacturing are equally remarkable. As global health agencies strive to eliminate TB, the role of bedaquiline manufacturers becomes even more crucial—ensuring that life-saving medicine reaches those who need it most, wherever they may be.

URL: For more information, visit Enanti Labs : Bedaquiline Manufacturer