AI in Manufacturing Autonomous Plants and Self Healing Systems

The manufacturing industry stands at a historic inflexion point as autonomous plants emerge as the new operational standard. AI in manufacturing has moved beyond incremental efficiency gains and entered an era where self healing systems and adaptive intelligence define competitiveness. What once were smart factories that merely alerted humans to problems are now evolving into autonomous plants capable of learning adapting and recovering without constant human intervention. This transformation is not about automation alone but about resilience speed and continuity shaping the future of global production.

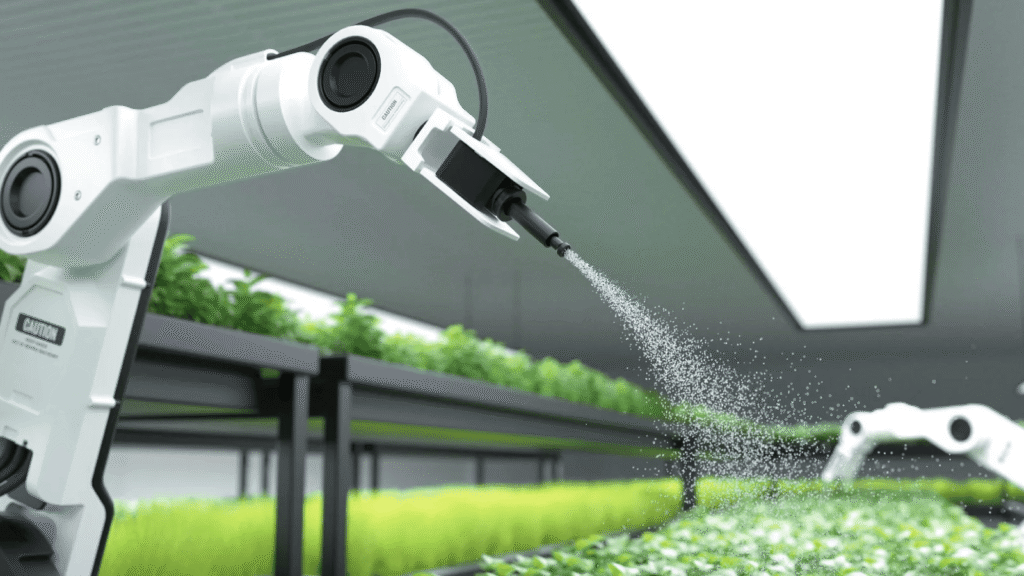

At the core of autonomous plants is the realization that efficiency without resilience is no longer sustainable. AI manufacturing systems now embed intelligence directly into machines processes and production flows. Reinforcement learning models enable equipment to respond dynamically to variability rather than reporting issues after damage occurs. These self healing systems continuously adapt tool paths thermal behavior and material tolerances ensuring production stability even during unexpected disruptions. This shift marks a decisive break from reactive operations and defines the next chapter of artificial intelligence news in industrial transformation.

Predictive maintenance once represented the pinnacle of AI in manufacturing but it still depended heavily on human response time. Autonomous plants go further by deploying prescriptive and self correcting intelligence. Using physics informed AI models connected to real time digital twins these systems detect anomalies identify root causes simulate corrective actions and apply solutions instantly. The result is a dramatic reduction in downtime and a fundamental redefinition of operational performance where mean time to repair becomes nearly irrelevant.

The value of autonomous plants extends beyond labor efficiency into strategic financial resilience. Capital utilization improves as AI manufacturing systems operate assets within optimal parameters around the clock. Dark factory operations become viable while self healing systems reduce exposure to geopolitical risk supply chain shocks and asset failure. In this context resilience value becomes a measurable competitive asset reinforcing why autonomous plants are increasingly featured across AI news and artificial intelligence news as a defining trend for 2025.

Edge intelligence plays a decisive role in enabling autonomy at scale. Autonomous plants rely on localized compute power to execute closed loop decisions without latency or dependency on centralized cloud infrastructure. Edge based AI manufacturing architectures ensure operational continuity even during network interruptions while supporting real time digital twins that reflect live system conditions. This architectural shift allows enterprises to deploy consistent autonomous intelligence across geographically distributed facilities reinforcing the global relevance of autonomous plants in manufacturing industry discussions.

As autonomy expands so does the cyber physical attack surface. Autonomous plants require integrated governance models that unite IT and OT security. Self healing systems must be transparent auditable and aligned with regulatory expectations. Explainable AI becomes essential to establish trust while zero trust principles protect interconnected machines and sensors. These governance imperatives are increasingly highlighted in industrial AI autonomous plants research and navigation driven searches across AI Tech Park manufacturing insights.

The human role within autonomous plants evolves rather than disappears. Operators transition into co pilots overseeing intelligent ecosystems and guiding strategic optimization. AI in manufacturing now demands digital fluency statistical reasoning and system orchestration skills. This transformation supports talent retention and positions organizations at the forefront of innovation reinforcing autonomous plants as both a technological and workforce strategy.

Autonomous plants are no longer experimental concepts but foundational pillars of modern industry. Organizations that embed AI manufacturing and self healing systems into their core strategy will define the next decade of industrial leadership. As artificial intelligence news continues to spotlight resilience driven growth autonomous plants stand as the clearest signal that the future of manufacturing belongs to systems that think adapt and heal on their own.

Explore AI TechPark for continuous AI news artificial intelligence news and expert insights on autonomous plants self healing systems and the future of AI in manufacturing.