In today’s fast-paced industrial world, manufacturers are constantly seeking ways to improve speed, precision, and cost-efficiency—and that’s exactly where the CNC cutting machine becomes a game-changer. From small fabrication shops to large-scale production facilities, these machines have redefined how materials are processed and products are made.

What Is a CNC Cutting Machine?

A CNC cutting machine is a computer-controlled device that automates cutting tasks using pre-programmed software. CNC stands for Computer Numerical Control, meaning the machine operates based on numeric codes generated from design files. These machines are used to cut a wide range of materials—metals, plastics, wood, foam, composites—with extreme accuracy and repeatability.

Instead of relying on manual operation, the machine follows digital instructions, reducing human error and allowing for complex shapes and high production volume with consistent quality.

Types of CNC Cutting Machines

Choosing the right CNC cutting machine depends on the material, desired finish, speed, and precision. Let’s look at the main types:

1. CNC Plasma Cutting Machine

Uses a plasma torch to cut through conductive materials like steel, stainless steel, and aluminum. Ideal for thick and durable metals.

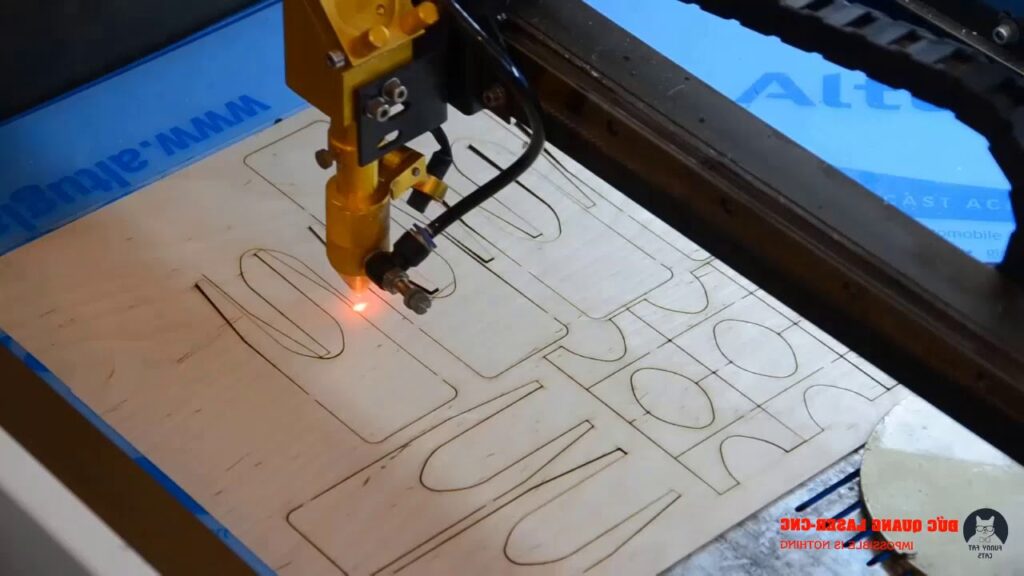

2. CNC Laser Cutting Machine

Uses a high-powered laser beam to cut thin materials with high precision. Excellent for sheet metal, plastic, and wood.

3. CNC Waterjet Cutting Machine

Employs a high-pressure stream of water (often with abrasive) to cut almost any material, including metal, stone, glass, and ceramics, without generating heat.

4. CNC Router

Primarily used for cutting softer materials such as wood, foam, acrylic, and soft metals. Commonly found in furniture and signage industries.

Each machine serves a distinct purpose, so understanding their strengths helps businesses make informed investment decisions.

How CNC Cutting Machines Work

The CNC cutting process starts with a digital design file, usually created in CAD (Computer-Aided Design) software. Here’s a simplified breakdown of the workflow:

- Design Creation: The part or product is designed in CAD software.

- CAM Programming: The design is translated into G-code through CAM (Computer-Aided Manufacturing) software.

- Machine Setup: Material is loaded, tools are checked, and zero points are calibrated.

- Cutting Operation: The CNC machine executes the cutting as per the code.

- Post-Processing: Parts may go through additional steps like deburring, cleaning, or coating.

This digital-to-physical workflow boosts precision, speed, and efficiency while minimizing waste.

Benefits of CNC Cutting Machines

1. Exceptional Precision

CNC cutting machines can maintain tolerances as tight as ±0.001 inches, allowing for intricate designs and highly detailed cuts. This precision is invaluable in industries like aerospace, automotive, and electronics.

2. High-Speed Production

Automated cutting processes reduce cycle times dramatically. With the right setup, a CNC cutting machine can run 24/7, delivering higher throughput and faster order completion.

3. Material Versatility

From hard metals like titanium to soft foams and plastics, CNC cutting machines can handle a vast range of materials. This versatility makes them suitable for multi-industry applications.

4. Reduced Human Error

Because the cutting is software-driven, there’s minimal room for manual mistakes. This improves product consistency and reduces scrap rates.

5. Scalability

CNC technology makes it easy to switch from prototyping to full production. Once a design is programmed, it can be replicated thousands of times without loss in quality.

CNC Cutting Machine Applications by Industry

| Industry | Application |

| Aerospace | Wing components, brackets, heat shields |

| Automotive | Chassis parts, engine blocks, interior components |

| Electronics | PCB housings, connectors, control panels |

| Medical | Surgical instruments, implants, equipment casing |

| Furniture | Custom wood panels, joinery, decorative elements |

| Signage | Acrylic letters, foam logos, LED signboards |

| Metal Fabrication | Structural components, panels, enclosures |

This wide range of uses demonstrates just how essential CNC cutting machines have become across modern industries.

Choosing the Right CNC Cutting Machine for Your Business

Before buying a CNC cutting machine, evaluate your business needs using these key criteria:

1. Type of Material

Not all machines are suited for every material. For instance, plasma cutters work best with metals, while laser cutters are better for thinner, non-metallic materials.

2. Required Tolerances

Precision matters. If your components demand tight tolerances, choose machines with high repeatability and advanced control systems.

3. Production Volume

If you’re producing in bulk, go for machines with automated tool changers, faster cutting speeds, and minimal downtime features.

4. Software Compatibility

Ensure the machine can integrate with your existing CAD/CAM systems. Seamless workflow improves efficiency and reduces learning curves.

5. Budget and ROI

Balance the machine cost against its output, lifespan, and maintenance needs. Though some machines may have a higher upfront cost, they often deliver better long-term ROI.

CNC Cutting vs Traditional Cutting: What’s the Difference?

| Feature | CNC Cutting Machine | Traditional Cutting |

| Precision | High (±0.001 inch) | Variable, depending on skill |

| Automation | Fully automated | Manual or semi-automatic |

| Efficiency | High-speed, 24/7 operation | Slower, limited by operator |

| Repeatability | Consistent output | May vary between units |

| Complexity of Cuts | Intricate, 3D, multi-layer | Basic to moderate |

| Waste Management | Minimal material waste | Higher chance of errors |

This comparison highlights the advantages of adopting CNC cutting technology, especially in competitive markets.

Maintenance Best Practices for CNC Cutting Machines

To ensure your machine performs optimally over time, follow these maintenance tips:

- Clean Daily: Remove debris and material residue after each use.

- Lubricate Components: Ensure all moving parts are well-oiled to prevent wear.

- Check Tool Condition: Replace worn-out bits, blades, or torches to maintain cutting quality.

- Calibrate Regularly: Precision requires frequent checks on positioning and alignment.

- Update Software: Keep machine firmware and software current to avoid compatibility issues.

Consistent maintenance not only prolongs machine life but also guarantees continued production efficiency.

The Future of CNC Cutting Machines

As technology evolves, CNC cutting machines are becoming smarter, more automated, and more energy-efficient.

1. AI-Powered Optimization

Advanced machines now use AI to detect cutting inefficiencies, suggest better tool paths, and self-adjust in real time.

2. Integration with IoT

CNC machines are becoming part of smart factories, where data is collected and analyzed for predictive maintenance, resource management, and workflow improvements.

3. Eco-Friendly Cutting

Waterjet and fiber laser machines offer cleaner operations with less energy and fewer emissions, aligning with sustainability goals.

4. Customization at Scale

Modern CNC systems allow for mass customization—producing unique parts in bulk without reprogramming each time.

These trends indicate that CNC cutting machines will continue to play a critical role in shaping the future of manufacturing.

Why Your Business Needs a CNC Cutting Machine

Whether you’re in a small shop or a large facility, investing in a CNC cutting machine brings significant benefits:

- Faster Turnarounds: Meet client deadlines and scale production with ease.

- Greater Accuracy: Deliver high-quality products consistently.

- Lower Costs: Reduce material waste and labor costs.

- Expanded Capabilities: Take on more complex and varied projects.

- Enhanced Market Competitiveness: Stand out with better efficiency and innovation.

In today’s world, where demand for speed, precision, and customization continues to rise, CNC cutting technology is not just an option—it’s a necessity.

Final Thoughts

The CNC cutting machine stands at the center of modern manufacturing. Its ability to deliver precision, reduce manual labor, and handle diverse materials makes it a vital tool across industries. Whether you’re fabricating aircraft parts or custom wooden panels, CNC cutting can take your production to the next level.

Investing in the right machine, maintaining it properly, and leveraging its full capabilities can give your business a competitive edge in quality, speed, and scalability. With smart automation, evolving technology, and sustainable practices, the CNC cutting machine isn’t just a tool—it’s a pathway to industrial success.