Underground Mining Drilling Rig Manufacturers: Driving Innovation Beneath the Surface

The underground mining sector relies heavily on advanced drilling technologies to extract minerals safely, efficiently, and sustainably. At the heart of these operations are underground mining drilling rig manufacturers—industry pioneers who design and build the specialized machinery that makes deep-earth excavation possible. Their innovations shape the future of mining, influencing productivity, safety, and environmental impact across the globe.

The Role of Drilling Rig Manufacturers in Underground Mining

Underground drilling rigs are sophisticated machines engineered to operate in some of the world’s most challenging environments. Manufacturers play a crucial role in:

1. Enhancing Safety Standards

Underground conditions can be unstable and hazardous. Manufacturers focus on developing rigs with reinforced structures, advanced monitoring systems, and automation features that minimize human exposure to dangerous areas. Ergonomic controls, stable drilling platforms, and real-time feedback mechanisms have become standard features that contribute to safer mining operations.

2. Improving Efficiency and Precision

Modern drilling rigs are designed to offer higher drilling speeds, greater accuracy, and minimal downtime. Manufacturers constantly refine hydraulic systems, drilling heads, and energy efficiency technologies to ensure rigs perform optimally even in complex geological formations. Precision drilling reduces material waste and improves ore recovery rates.

3. Supporting Modern Mining Techniques

As mining evolves—from traditional blasting methods to continuous mining technologies—drilling rigs must adapt. Manufacturers invest in research and development to produce rigs compatible with modern techniques such as long-hole drilling, raise boring, and exploratory core drilling. These advancements help mining companies maximize output while minimizing operational costs.

Key Features of Today’s Underground Mining Drilling Rigs

Underground drilling equipment has evolved significantly over the past decade. Some of the most common features offered by manufacturers today include:

● Automation and Remote Control

Many rigs now include automated drilling cycles and remote-operated capability, allowing operators to manage drilling from a safe distance. This not only boosts safety but also improves consistency in drilling quality.

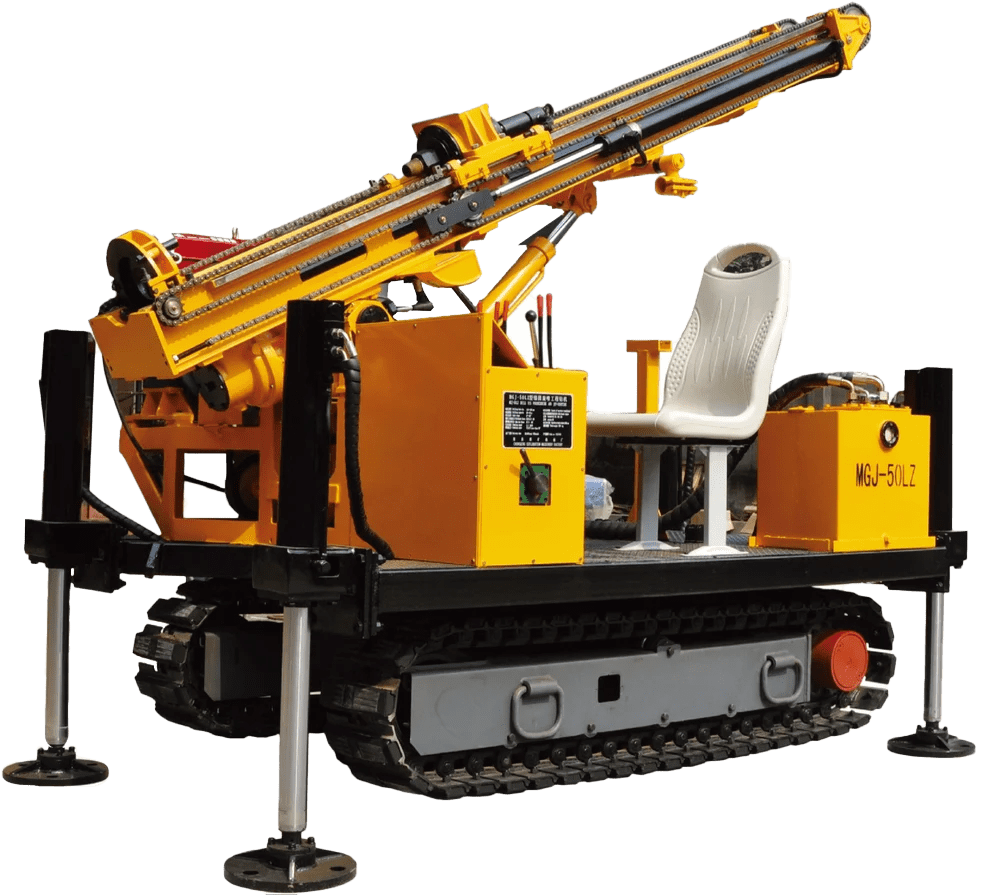

● Compact and Flexible Designs

Space is limited underground, so manufacturers develop rigs that are compact yet powerful. Articulated frames, low-profile designs, and flexible booms help rigs navigate narrow tunnels and tight corners.

● Energy-Efficient Systems

To reduce fuel consumption and environmental impact, manufacturers integrate energy-saving hydraulic systems, electric motors, and hybrid technologies. These innovations support sustainability goals while cutting operational expenses.

● Advanced Data and Monitoring Tools

Real-time drilling data, machine diagnostics, and performance reporting tools help mining teams make informed decisions. Manufacturers incorporate IoT-enabled systems for predictive maintenance and improved reliability.

Challenges Facing Drilling Rig Manufacturers

Despite significant advancements, manufacturers face unique challenges:

- Harsh working environments require robust designs that can withstand vibration, heat, dust, and moisture.

- Rising operational costs push manufacturers to innovate while keeping equipment affordable.

- Sustainability pressure encourages a shift toward eco-friendly materials and low-emission systems.

- Skill shortages in mining technology compel manufacturers to simplify controls and enhance automation.

These challenges drive continuous innovation, pushing the industry toward more advanced and efficient drilling solutions.

The Future of Underground Drilling Equipment

The future of underground mining drilling rigs points toward smarter, cleaner, and more autonomous operations. Trends to watch include:

● Fully Automated Drilling Systems

With AI-driven analytics and autonomous navigation, future rigs may require minimal human intervention, resulting in higher precision and reduced risks.

● Electric and Hybrid Drilling Rigs

Electric rigs reduce emissions in closed underground environments and align with global decarbonization goals.

● Integrated Digital Platforms

Seamless data sharing between drilling rigs, control centers, and geological models will optimize entire mining workflows.

● Enhanced Safety Through Robotics

Robotic assistance will likely take on more dangerous tasks, improving safety metrics across mining operations.

Conclusion

Underground mining drilling rig manufacturers are essential to the continued growth and modernization of the mining industry. Through constant innovation, they help mining operations become safer, more efficient, and economically viable. As global demand for minerals increases, the importance of advanced drilling technologies—and those who build them—will only continue to rise.

URL: For more information, visit Beaver Tracks : Under Ground Mining Drilling Rig Manufacturers